Introduction

Woodframe multi residential buildings with hardwood or tile floors frequently have impact isolation problems between floors. In many cases, such buildings may not have the requisite robust partitions between spaces. Often, the floors between units do not have enough mass and decoupling for proper impact and sound isolation.

David Coate Consulting was hired to design and recommend necessary floor treatments for this project located in Scituate, Massachusetts.

The Uniform Building Code requires an STC and IIC (Impact Isolation Classification) of 50 (45 if field-tested). DCC conducted both tapping machine tests as well as airborne Noise Level Reduction (NLR) Tests to determine the impact and sound isolation characteristics of the existing structure.

Test Results

Airborne Sound

Airborne sound refers to the transmission of sound from one space to another when there is no physical impact on the structure causing the sound. Examples of airborne sound would include voices and music playback systems. The NLR, the difference between noise levels in your unit and above the 2nd floor, measures how effective that partition is in terms of airborne sound isolation. I measured the NLR of this partition by reproducing pink noise through a high performance sound system and measuring the difference in noise levels in 1/3 octave bands.

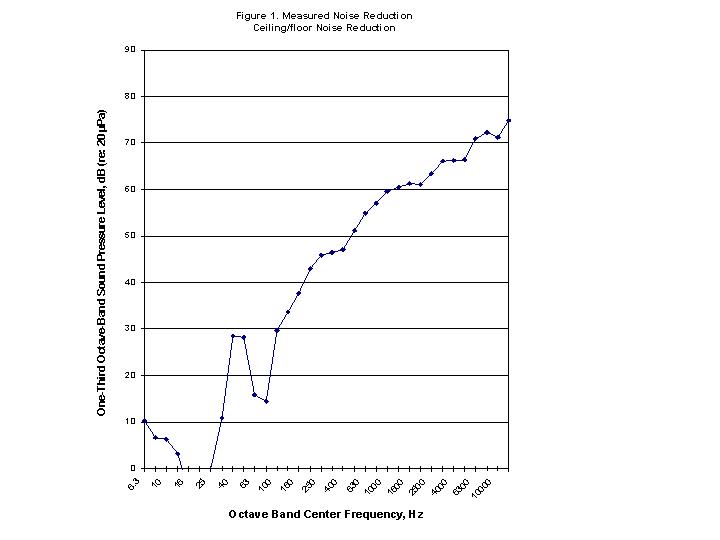

Figure 1 shows the measured NLR in 1/3 octave bands for the ceiling/floor partition. This NLR corresponds to STC 55 which exceeds the UBC STC requirement of 50.

Impact Sound

I conducted impact isolation testing in accordance with Standard Test Method for Field Measurement of Tapping Machine Impact Sound Transmission through Floor-Ceiling Assemblies and Associated Support Structures. (ASTM E 1007-04). A total of 16 1/3 octave band spectra are required, each associated with four different tapping machine positions and four microphone positions in the receiving room. In addition, the procedure calls for measurement of the RT60, the reverberation time of the receiving room (in this case, your unit) to normalize the results to a standardized room absorption. The floor/ceiling tested at FIIC 39, which is substantially less than the UBC Code requirement of FIIC 45 or greater.

Treatment Options

The fact that the airborne sound tests demonstrated acceptable levels while the impact tests demonstrated unacceptable levels indicates that this is primarily a structural transmission problem. The requisite treatment options would decouple the floor and ceiling, thereby minimizing the transmission of impacts on the floor to the ceiling below. Decoupling can be accomplished by either installing a floating floor above or a resiliently mounted ceiling below. Increased performance is achieved by increasing the size of the airspace, resiliency, and/or mass of the floated floor/ceiling. In this case, a floating floor could be considered, but it would increase the floor height by several inches which in turn would require door thresholds to be refitted and the installation of a new hardwood floor. Because of the potential intrusiveness of this approach, our primary recommendation would be to install a resiliently mounted ceiling in your unit.

Option 1. Kinetics ICW Ceiling Hanger

Kinetics Noise Control’s ICW ceiling hanger (shown in Figure 2) provides the highest sound isolation performance, but the installation would be somewhat intrusive. According to Kinetics test data, a floor consisting of 3/8” wood floor, 5/8” plywood, 2x10 floor joists, fiberglass batt in the cavity, and two layers of 5/8” Gypsum Wall Board (GWB) suspended using ICW hangers, would achieve STC 59 and IIC 52. However, the hanger mounts on the side of the joist, so large holes would need to be cut in the existing ceiling where the hangers would be mounted. Drywall furring channel would be mounted on the spring loaded piston of the hanger, and the GWB would be mounted on the furring channel. The furring channel and new GWB would not touch the existing joists.

Two construction methods are possible. One would be to tear down the existing ceiling, mount the hangers on the joists, install furring channel, and the drywall. This approach would result in a reduction of ceiling height of approximately 2 1/2”. The previously mentioned approach of leaving the existing ceiling and cutting holes for the hangers would result in a reduction of ceiling height of approximately 4 5/8”.

A small gap (nominally ¼”) around the perimeter of the GWB should be provided and filled with non-hardening acoustical caulk. If the new ceiling is installed in this manner, it should ‘give’ when pushed upwards.

Either blown in or batt insulation is assumed for this option, and the existing cavity would need to be approximately half-filled. Insulation in the cavity provides little sound isolation per se, but it helps to reduce the magnitude of cavity resonances, and therefore usually provides a few additional decibels of attenuation. Lighting fixtures, sprinkler heads, and ductwork would need to be reconfigured in order to not penetrate the new ceiling or cause rigid connections with the structure. Recessed lighting can be accommodated by building GWB boxes over the receptacles which would provide essentially the same mass isolation as the rest of the new ceiling. Other materials with sufficient mass (such as steel) could be used instead.

The ICW hanger costs approximately $27 apiece. It is likely that the labor involved in installation of the hangers and new ceiling would be substantial, but not as involved or as intrusive as the installation of a floating floor.

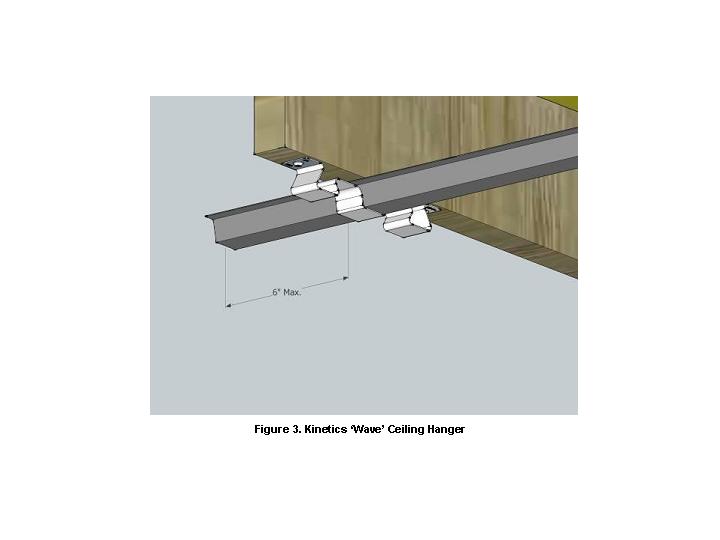

Option 2. Kinetics Wave Ceiling Hanger

Another lower cost option would be to install the new ceiling using Kinetics new ‘Wave’ ceiling hanger shown in Figure 3. The hangers themselves are $5 apiece and the new ceiling can be installed directly on the existing ceiling. Two layers of 5/8”GWB would be installed on furring channels connected to the Wave hangers. The hangers would be mounted on the existing ceiling and screwed into the existing joists. Care needs to be taken to not ‘short –circuit’ the resiliency of the hangers by accidentally screwing the GWB to the joists. This option would lower the ceiling by approximately 2 ¾”. Option 2 would also include the blown in insulation and perimeter caulking discussed in Option 1.

For this option, it is important to cut holes in the existing ceiling to allow air into the new airspace created by the installation of the new ceiling. Otherwise, resonances in the unvented airspace may degrade the isolation performance. This can be accomplished by cutting 5” diameter holes in the ceiling in each joist cavity, spaced no more than 6’ apart.

Option 2 should approximately achieve an IIC of 46 or 47, which would be a very noticeable improvement.

Option 3. Add IsoLayment BR to Option 2.

It is quite possible that the implementation of Option 2 will provide satisfactory results, although impact sound might still be audible. However, if additional isolation performance was needed, Kinetics IsoLayment BR could then be installed. IsoLayment BR is a 1/8” thick layer of rubber which could be installed directly on top of the wood floor in the unit above yours, and another wood floor would then be installed on top of the rubber. Kinetics has tested a similar configuration at IIC 57. Please note that even though this is a large increase in performance compared with Option 2, the addition of the rubber primarily improves the mid-frequency isolation performance. The ceiling hanger approach is needed to obtain very important low-frequency sound isolation.

Other Issues

Because a phased approach may be desirable for this project, it may be prudent to test the selected treatment option(s) on one room of your unit such as the study. If the results and costs are favorable, you could then proceed to treat your entire unit and/or other units in the building. However, there may be unfavorable economies of scale with this approach. Based on the data in this report, you should obtain bids from reputable contractors. If the relocation/boxing in of lights, ductwork, and sprinklers becomes involved, you may want to contract an architect for assistance.

You also may want to conduct NLR and isolation impact testing once the treatments are installed, but that may not be necessary if the results are completely satisfactory.

Please note that large improvements in the IIC have been found by adding a thick carpet pad and carpet to areas upstairs where footfall noise is heard. Obviously this is a relatively simple and inexpensive avenue to try out. Technically, this approach should eliminate the need for the Isolayment BR if carpet is acceptable in certain areas.